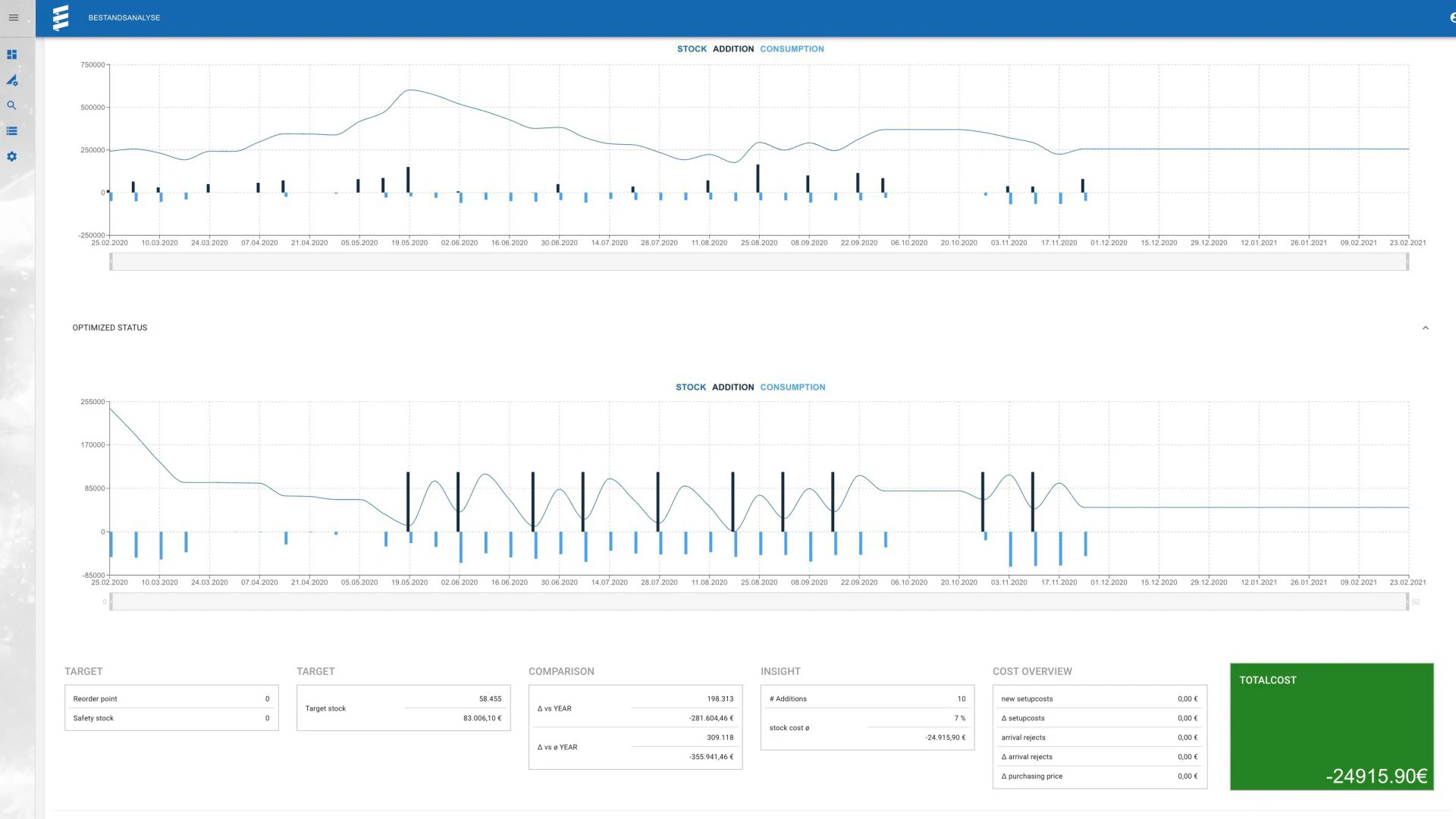

KPI Tracking & Business Intelligence

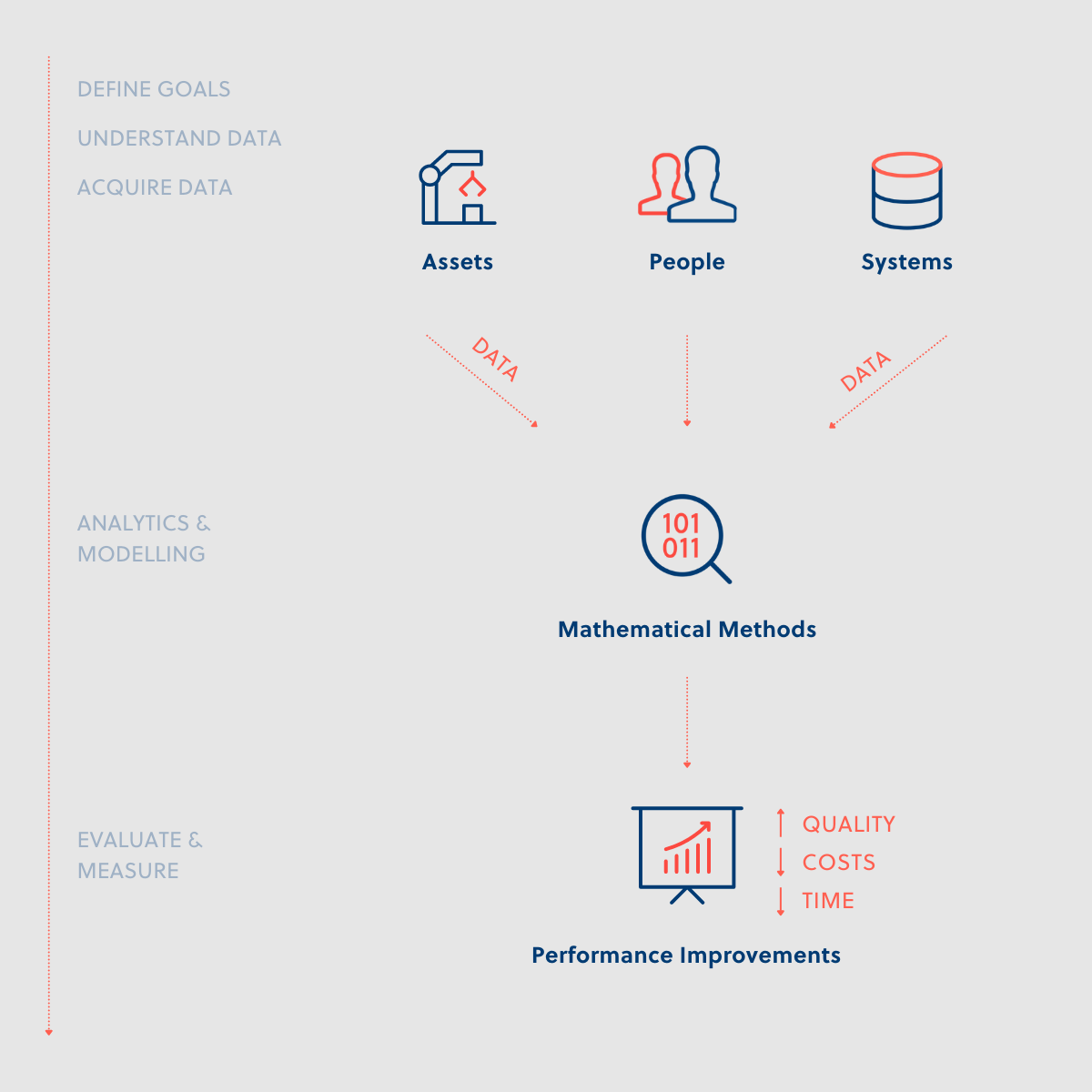

In this simple form of data analytics, data is used to calculate and visually prepare relevant key performance indicators. The KPIs are used to control individual processes in day-to-day business.

The preparation of real-time data represents one of the basic principles of Industry 4.0 and digitization and is therefore a central component in almost all NEONEX transformation projects (see image gallery). Small, independent entry-level projects in production and supply chain also lend themselves to the field.

Exemplary applications are:

- Automated creation of reports

- Visual real-time representation of processes and performance on the store floor with dashboards & drill-down analyses