Inventory AnalytiX

Data-driven Inventory Optimization

Use supply chain analytics & simulation to manage inventory efficiently

👉 ☑️

Inhalte von YouTube werden aufgrund der von Ihnen gewählten Einstellungen zum Datenschutz nicht dargestellt. Um YouTube Videos zu aktivieren, gehen Sie bitte auf die "Datenschutzeinstellungen" und akzeptieren Sie alle Cookies.

High stocks? Low service level?

Inventories are a daily challenge for production planning: Planning the right amount of different raw materials and articles is complex, especially with an increasingly broad product portfolio. Those responsible in material planning are all too often faced with a dilemma: Too many stocks tie up liquidity, too few jeopardize delivery performance and thus customer satisfaction. Conventional forecasting and scheduling functions in ERP systems are increasingly reaching their limits here. In many places, the resulting costs, at 9-15% of the total inventory, are a significant cost item in the income statement.

Use data ... and supply chain knowledge

We offer you the opportunity to uncover considerable potentials for inventory optimization within two weeks. These are based on various algorithms and analyzes as well as the relationships between different supply chain parameters. Successful implementation of the jointly defined measures usually lead to a permanent reduction in inventory costs between -10 to -30%. The service level can be increased by up to 15%.

Reduce costs

Realize savings of up to 30%

Increase service level

Increase delivery reliability by up to 15%

Our consulting package

Process parameters such as the lot size and the replenishment lead time have a decisive influence on which quantity of an article has to be ordered and when.

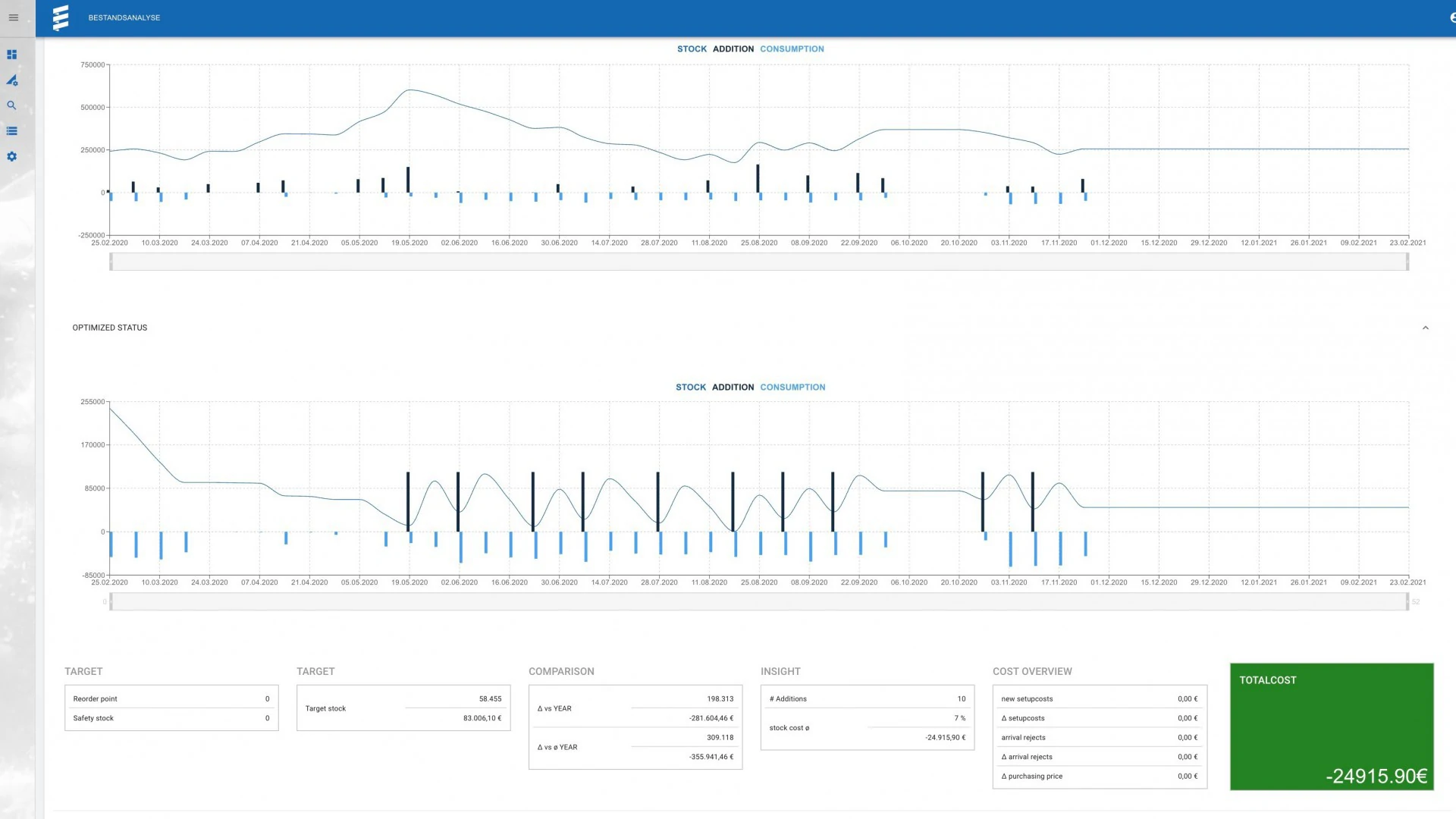

That is why we use our exclusively designed supply chain analytics tool, which determines the future target inventory based on ERP data and the desired service level. The high visual transparency shows very intuitively the need for changes, such as master data adjustments and lot size optimizations.

Next, we qualify your employees: with supply chain training tailored to your needs. In this way, the supply chain know-how is improved and the relationships in an end-to-end supply chain become clear. This step is necessary to gain an understanding of the simulation processes and derived measures.

On the basis of the supply chain training and the analysis and simulation results, we discuss the potentials and risks in your current inventory situation and optimization measures together.

As part of an implementation support defined with you, we regularly discuss the necessary improvement measures with your planners and procurers, which are based on methods from the supply chain and LEAN management. The aim here is that your employees learn how to improve inventory and service sustainably so that they can carry out such measures independently in the future.

Inventory optimization in three steps

Analyze data + simulate changes

You provide movement data from the ERP system and material master data for your articles.

We work with you to check the plausibility of the data in advance.

Our supply chain experts combine the data in the inventory optimization software developed by NEONEX. Various algorithms are used to simulate how a change in various planning data and processes (e.g. replenishment lead time, lot size, requirement smoothing) affects the overall costs, i.e. what potential for cost savings results.

Understand supply chain + discuss measures

By means of an individually structured training, the supply chain know-how of your employees is improved and an understanding of relationships in an end-to-end supply chain is built up.

On the basis of the supply chain training and the analysis and simulation results, we discuss the potentials and risks in your current inventory situation and possible optimization measures.

Implement necessary changes

As part of the implementation support, we discuss the improvement measures for selected items with your planners and procurers on a regular basis (e.g. monthly).

We jointly follow the results achieved and discuss any challenges during the operational implementation.

Our Inventory AnalytiX tool

- Real-time visualization: The software displays all ERP master data and process data quickly and clearly

- Inventories over time: You can see at a glance how your total inventory and the inventory of each individual item has changed over time.

- Savings potential: Based on the current supply chain data, there is a total potential of how much costs could be saved by optimizing the inventory

- "What-if-Scenarios": Simulation of process changes in real time: Make changes to parameters such as lot size and use the simulation to find the ideal processes for an optimal inventory.

Why NEONEX?

NEONEX is a management consultancy with technical and management expertise. We come from industry. With our in-depth knowledge, we develop functional concepts to increase the competitiveness of our global customers and accompany them from the first step through to global roll-out.

Thanks to our extensive know-how, we were able to develop an analysis and simulation tool that clearly visualizes the complex relationships in a supply chain and very easily shows potential for improvement.

Decide with Inventory AnalytiX to intelligently optimize your inventory instead of reducing it across the board.

Questions? Ask our expert

Contact

Results

- Inventory: - 10%… - 30%

- Service level: + 5% ... + 15%

- Qualified team

-Feedback on your supply chain parameters

Duration

2 weeks + individual implementation support