How can you transform or specifically optimize your supply chain to sustainably strengthen your market position? We accompany you with analysis, strategy, implementation and success measurement in transformation and optimization.

Globalization and digitalization pose new challenges to the supply chains of almost all companies: Strong competitive pressure due to significantly increased transparency, shorter product life cycles, the trend towards individualized products and global supply chains entail high risks for companies.

Sensible and necessary adjustments to supply chains have often not kept pace with these changes. Formerly good processes are thus no longer in line with the market and often inefficient. When unexpected events occur, this manifests itself in poor delivery performance, high false inventories, and high manual planning and scheduling efforts. It also results in micro-management, which manifests itself in the discussion of inadequacies with customers in sales, high procurement costs for raw materials and components in purchasing, and inefficiencies in the entire operation due to permanent rescheduling, along the entire supply chain. Against this background and the resulting changes in costs and risks, existing processes and structures need to be reviewed and realistically evaluated

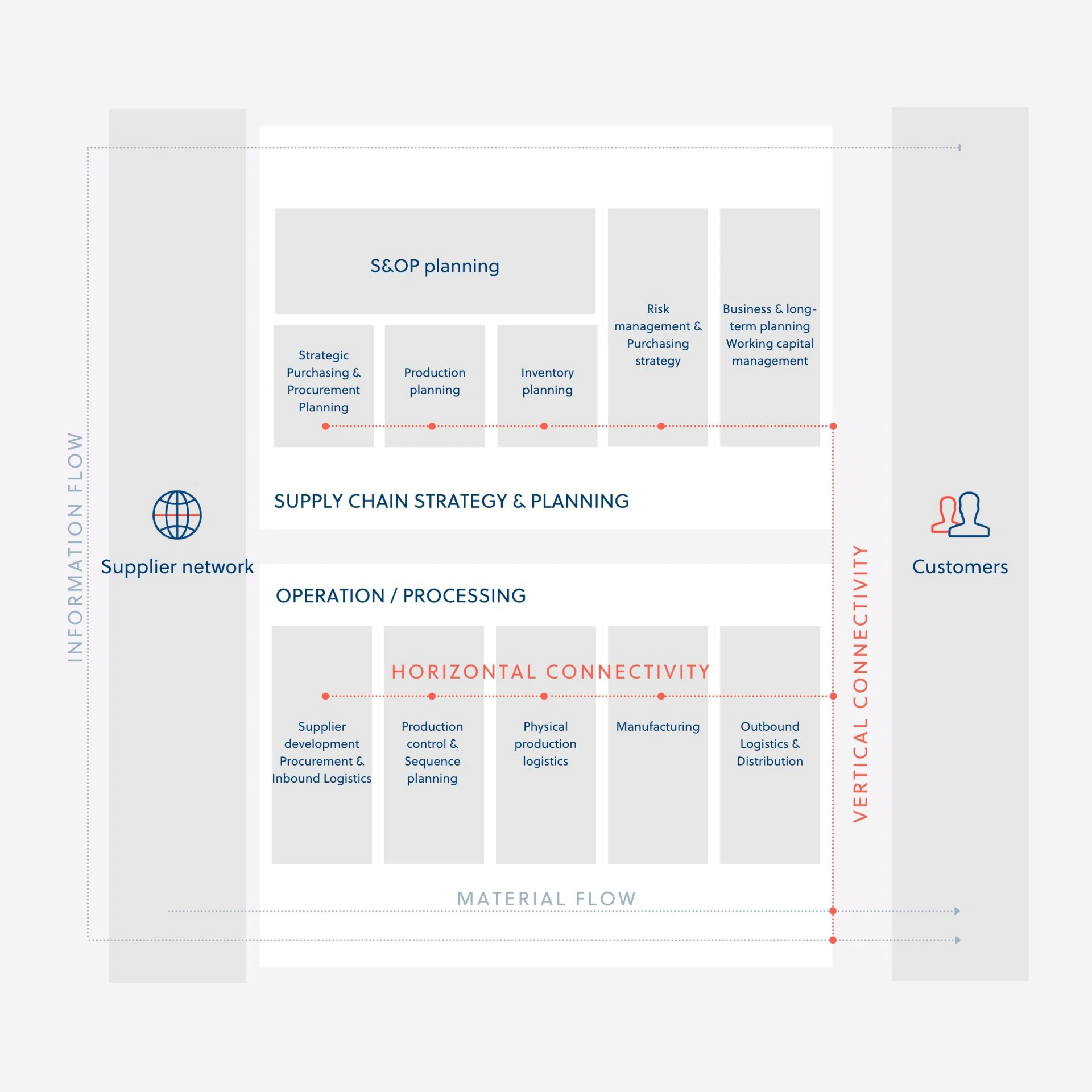

Together with you, we build your supply chain in a future- and customer-oriented way so that it becomes adaptable and robust to change. To achieve this, we understand your supply chain holistically and include all affected business processes. Our approach is data-centric, agile and uses digital technologies wherever it makes sense.

The NEONEX Success Factors

Our many years of supply chain and lean management experience as in industry and consulting, combined with deep know-how from our transformation projects and in change management, are important success factors to build your supply chain agile, scalable and resilient. For this, we start at the core of your value creation processes with planning and implementation to achieve results quickly & efficiently.