Selection and Implementation of PLM Systems

Introducing end-to-end processes for product lifecycle management

The number of variants in product portfolios of many industrial companies is growing continuously, resulting in ever-increasing complexity in their development, supply chain, production, sales and service. Modern Product Lifecycle Management (PLM) systems support companies in overcoming this complexity. We support you in the selection and implementation of a PLM system and the associated transformation.

In many cases, industrial products are a highly integrated combination of mechanical and electronic components, as well as the associated software. Changes, especially to product requirements or product design, have a whole range of implications for purchasing, production and service. Which parts are affected by a change to an individual component is often not a simple question. In addition, it is increasingly difficult to maintain an overview of the necessary follow-up steps and their completion.

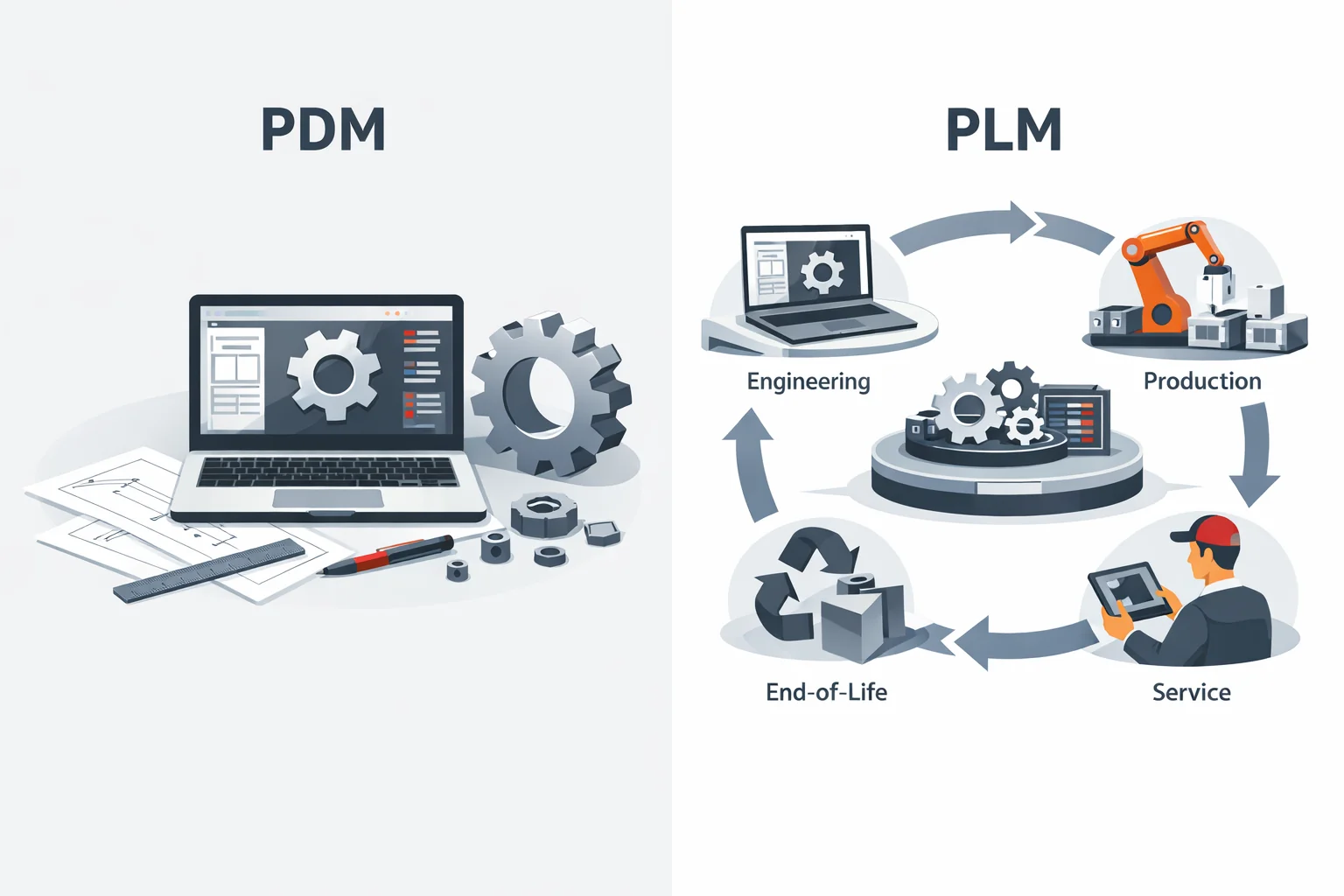

In this context, Product Lifecycle Management is much more than just software; it is a new type of company-wide collaboration with integrated data and processes.

The benefits of PLM systems

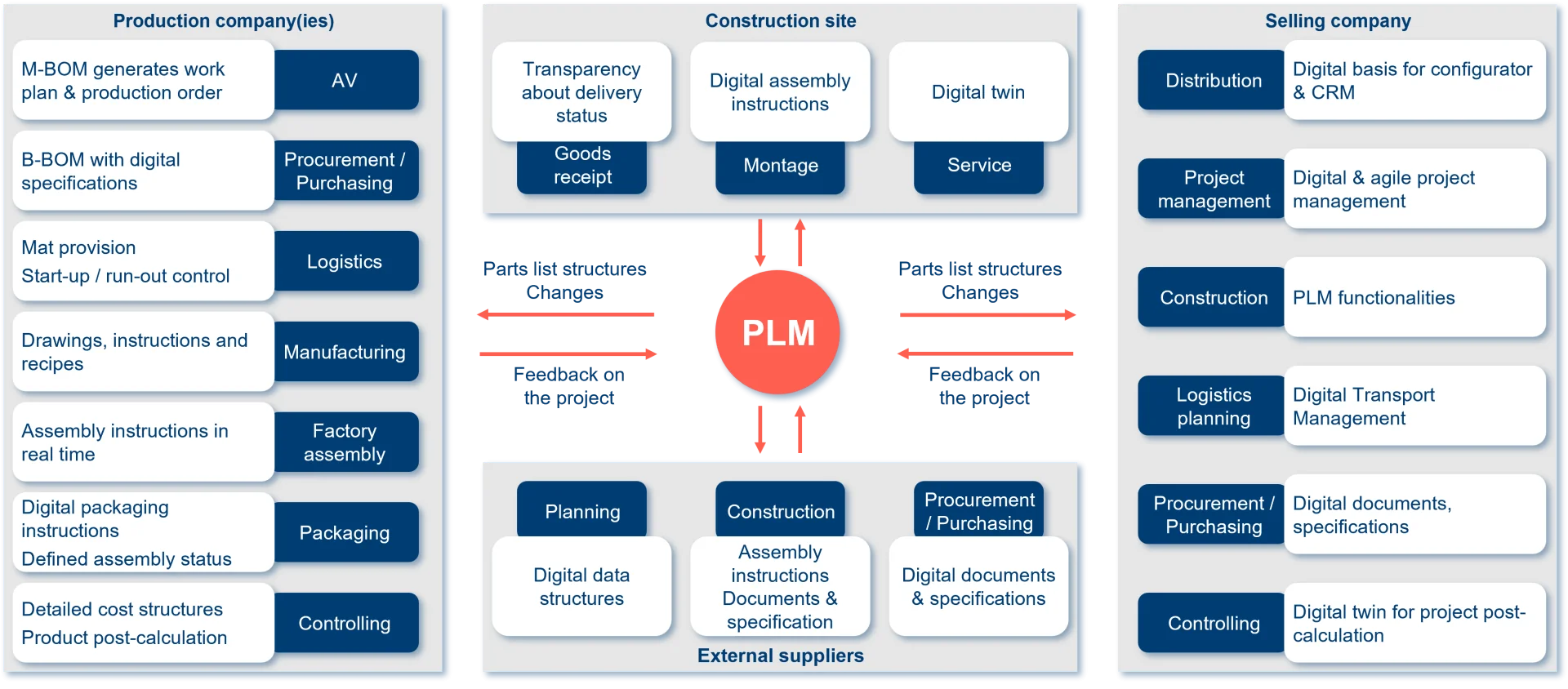

Modern PLM systems support companies in these diverse and challenging tasks. On the one hand, PLM systems manage a wide variety of product data (requirements, product structure, drawings), but also their relationship to each other and to other components such as software, standard parts catalogs, etc. The interfaces to authoring systems such as CAD systems and to the systems that use this data, such as sales configurators or after-sales service systems, are particularly important here.

The various bills of materials (BOMs) for the respective purposes, such as software BOMs for all software components of a product and specific BOMs for purchasing, production, sales and service, are central to this. Each department requires this data in a structure tailored to its needs.

On the other hand, processes are mapped in detail in PLM systems to create, change and connect the mentioned data as efficiently and error-free as possible. A central component of this is a clear roles and rights concept that defines which employees can make which changes using which processes. One example would be the short-term changes and approval of a component by the work preparation department with a so-called “fast track” for a prototype, while components for ongoing production must remain unaffected by such changes.

The implementation of a PLM system is a transformation

A PLM system implementation is not just a software project, but a company-wide transformation. Behind this transformation is the strategy of managing complexity and integrating indirect activities into end-to-end business processes with end-to-end data.

The human factor - but also a consistent end-2-end approach to processes and the associated data - plays a major role here. Seamless integration increases the competitiveness of companies in the long term, also by reducing the speed of response.

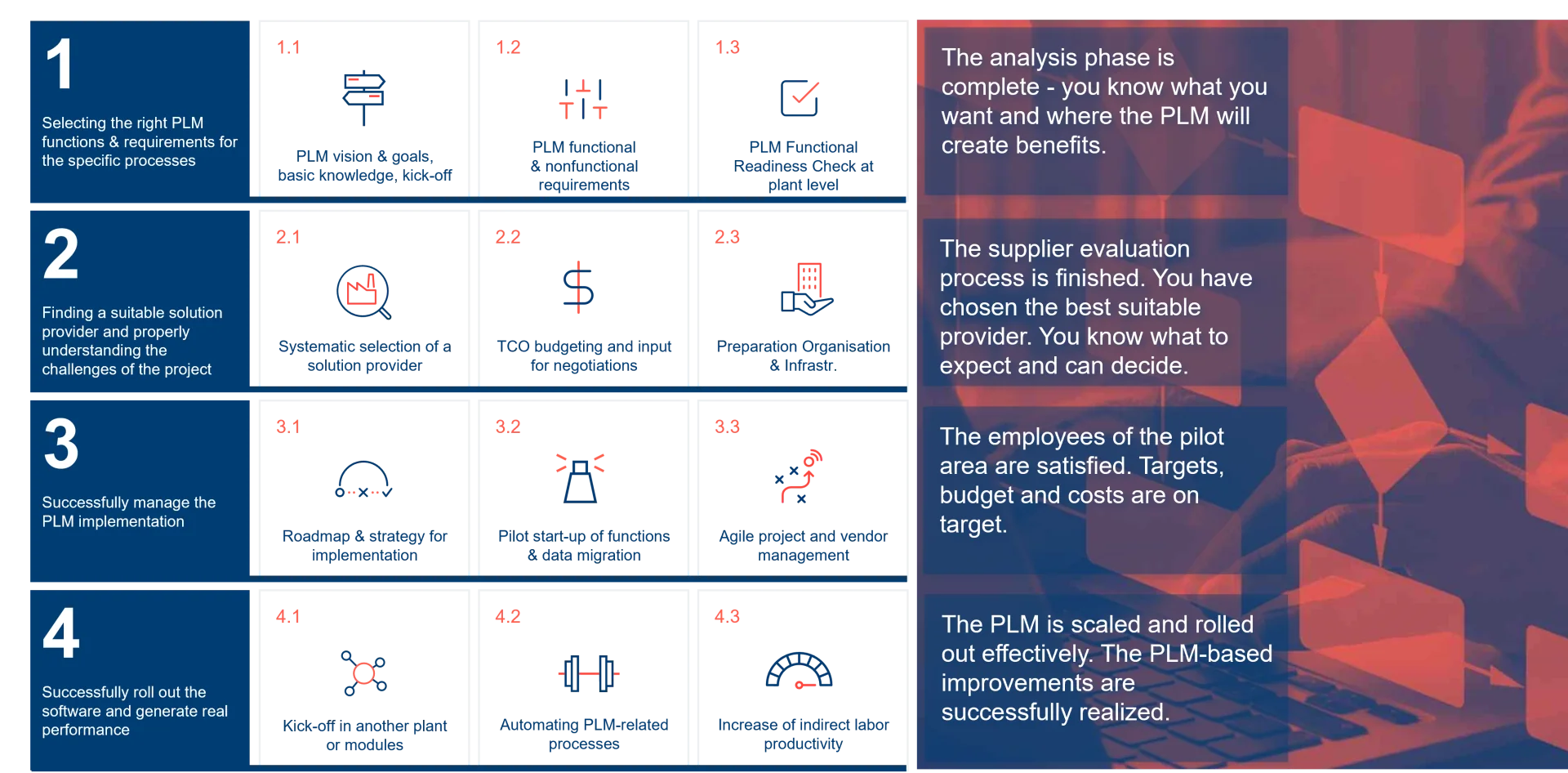

We support you at the start of this transformation with a four-stage approach.

Example of the target state of PLM implementation at a plant manufacturer.

Four phases to realize a real performance increase in the company with a PLM introduction

Requirements analysis

Together with all stakeholders, a holistic target picture is defined for the contribution of a consistent PLM strategy from development to sales, production and service. The role of PLM in the respective areas of the company is also aligned within this phase.

Based on a comprehensive analysis, challenges in today's business processes are identified and prioritized across the entire company. Consistent end-2-end target processes are defined for prioritized business processes and the associated functional requirements are derived.

The associated data requirements and non-functional requirements are defined subsequently.

As a final step in this phase, a functional readiness check identifies all open issues before, during and after the PLM implementation and includes them in a structured and prioritized gaps and measures list so that you are optimally prepared for the transformation.

Supplier selection

Based on the functional and non-functional requirements, a structured and transparent selection process is carried out, which leads to the most suitable supplier in several stages.

From more than 100 potential suppliers in our supplier database, a short list and finally the top 3 candidates for supplier pitches are selected efficiently and in a structured manner from a long list. The tried-and-tested, professional procedure avoids lengthy consultation loops. The entire selection process is much more efficient for everyone involved.

In addition to meeting the technical requirements, soft factors also play a decisive role in supplier selection: How well has the supplier understood the task and the company's specific challenges? How should project management be structured? Which provider can support a global rollout?

Implementation

A key success factor is a coordinated, stringent introduction to the solutions and processes with all relevant employees involved. A clear pilot and rollout strategy as well as a definitive migration plan ensures focus and speed. The coordinated vision, the preparatory steps from the requirements definition and the early processing of the identified gaps and measures are now bearing fruit.

Agile project management throughout the entire rollout guarantees fast, user-oriented results and avoids the risk of disappointment after long development cycles.

Transformation & Scaling

As the functionalities introduced are scaled to other locations and business units, the benefits of the initial project investment are continually increased. The vision of integrated end-2-end processes grows step by step with the implementation phases.

It is important to reach the “Ready to Deploy” state. This means that all potential improvements identified during the introduction phase are implemented so that a solution that is ready for roll-out can be implemented across the board.

The human factor is also crucial here: a successful transformation ultimately means a change in working methods and sometimes also a change in roles and experience horizons within the company.

NEONEX success factors

AAs independent process and technology experts, we quickly understand your processes and accurately assess whether a system-based solution is suitable for various challenges. This enables us to evaluate jointly in which system this solution can be optimally anchored. We know exactly what is important in the specific company processes for a genuine End-2-End improvement and how the associated data flows need to be designed.

Another important success factor is the speed that we bring to your transformation. This speed builds and maintains momentum in the change. Thanks to our professional, tried-and-tested approach and our knowledge of providers, we work with you to find the most suitable solution provider for you efficiently and without any unpleasant surprises.

We have already been able to demonstrate our expertise in numerous PLM projects with manufacturers. We would also be happy to support you in your organization’s transformation.

We are at your disposal.

Ihr Ansprechpartner